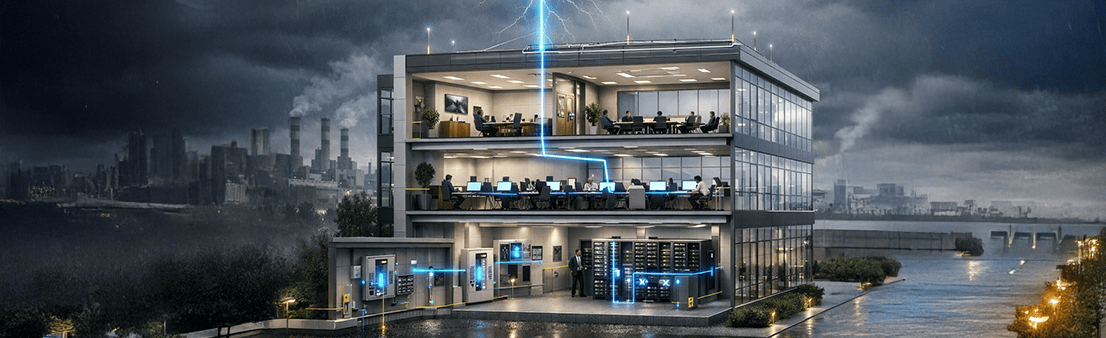

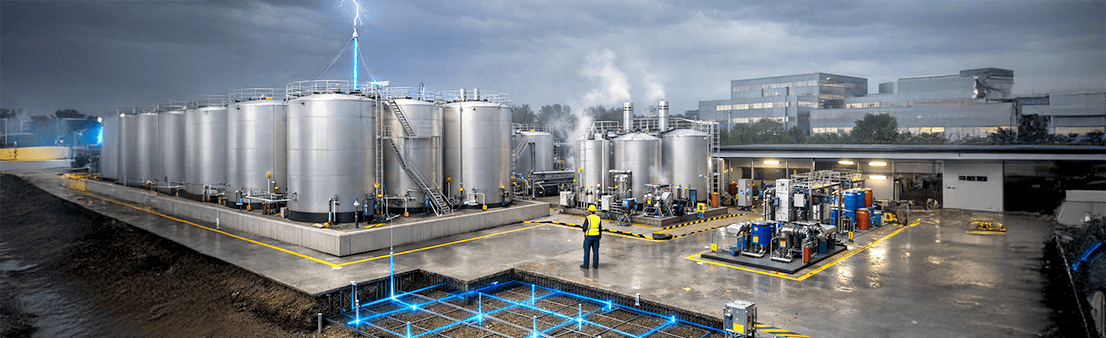

Lightning & Surge Protection Solutions for FMCG Manufacturing Facilities

In FMCG manufacturing environments, electrical resilience is a core operational requirement. High-density infrastructure,continuous production cycles, automation-driven processes, and digital dependency make FMCG facilities highly exposed to lightning strikes and transient overvoltage events.

LPES provides engineered lightning protection systems (LPS) and coordinated surge protection solutions designed to safeguard FMCG buildings, warehouses, production assets, power infrastructure, automation systems, data networks, and workforce safety—in full alignment with international standards and global compliance frameworks.

Integrated Lightning Risk Management for FMCG Facilities

Lightning Protection Architecture (As per IEC 62305)

External Lightning Protection System (LPS)

Internal Surge Protection (Coordinated SPD Network)

Earthing & Equipotential Bonding System

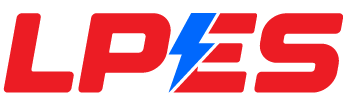

Manufacturing & Production Zones – Highest Criticality Areas

FMCG production environments operate on tight takt times and automated control systems, where even microsecond disturbances can cause equipment failure or production loss.

- Continuous production and batch processing

- High dependence on PLCs,VFDs, servo drives,and automation

- Fire and explosion risk in oil,aerosol, and alcohol-based processes

- Production halls and sheds

- Processing lines (mixing, filling,packing, bottling)

- Machine control panels and MCCs

- Control rooms and automation cabinets

- Utility rooms (boilers, compres

- Air termination systems (lightning rods/roof conductor mesh)

- Down conductor networks

- Equipotential bonding of metallic systems

- Type 1 and Type 2 SPDs for machinery and automation panels

- Raw material warehouses

- Finished goods distribution centers

- Cold storage and temperature-controlled facilities

- High-bay and high-rack storage buildings

- Direct lightning-induced fires

- Failure of refrigeration and material handling systems

- Large-scale inventory loss and supply chain disruption

- Roof-mounted lightning arresters

- Structural earthing and bonding

- Surge protection for lighting, power, and refrigeration systems

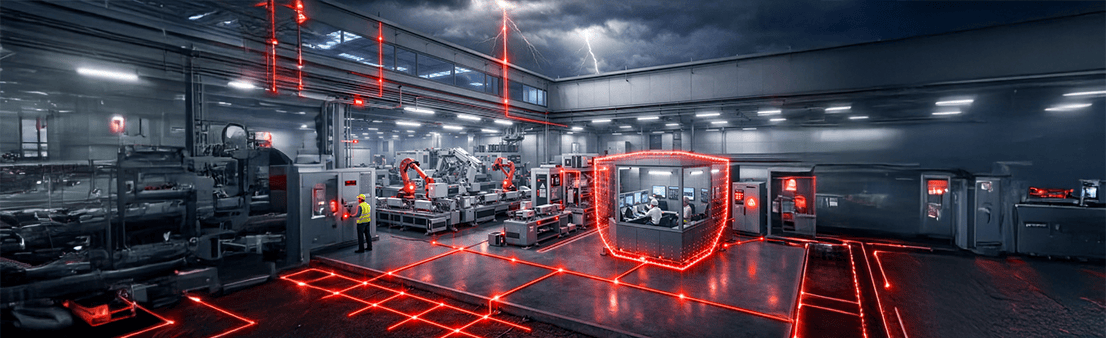

- HT and LT incoming panels

- Transformers and substations

- Diesel generator (DG) systems

- UPS and critical power rooms

- SPDs at service entrances

- SPDs at downstream distribution boards

- Low-impedance earthing systems

- Surge event counters and monitoring devices

- Direct and indirect lightning surges

- Utility switching and load fluctuations

- Ground potential rise and poor earthing

- Sensitive downstream electronic loads

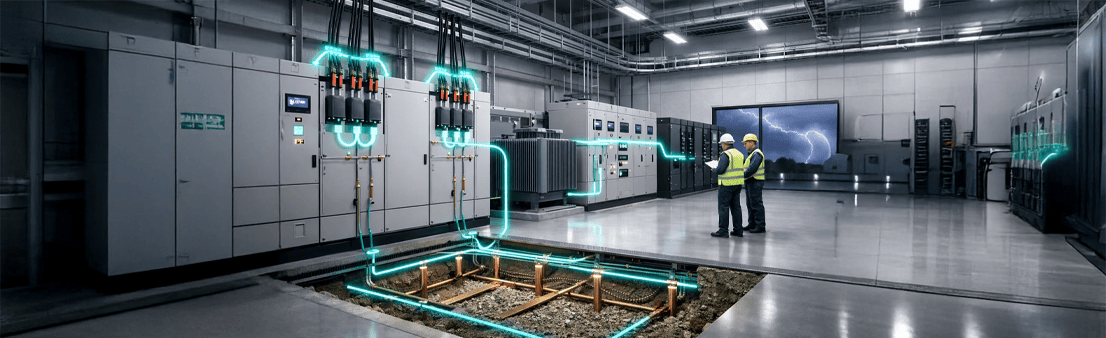

- Server rooms and data centers

- PLC, SCADA, and DCS networks

- Production monitoring and quality systems

- Weighing, barcode, and traceability systems

- Direct lightning-induced fires

- Failure of refrigeration and material handling systems

- Large-scale inventory loss and supply chain disruption

- High-speed automated production lines

- Continuous data acquisition and ERP integration

- Sensitive electronic controls and sensors

- Regulatory-driven traceability requirements

- Water treatment plants (WTP)

- Effluent treatment plants (ETP)

- Pump houses and cooling towers

- Fire detection and firefighting systems

- Lightning rods and interception systems

- Surge protection for motor control panels

- Earthing and bonding of exposed metallic structures

- Outdoor and exposed installations

- Long power and control cable runs

- Motor-driven and rotating equipment

- Safety-critical and life-protection systems

- Water treatment plants (WTP)

- Effluent treatment plants (ETP)

- Pump houses and cooling towers

- Fire detection and firefighting systems

- Lightning rods and interception systems

- Surge protection for motor control panels

- Earthing and bonding of exposed metallic structures

- Flammable vapour accumulation zones

- Electrostatic charge buildup risks

- Direct lightning strike exposure

- Ignition from transient overvoltages

- Water treatment plants (WTP)

- Effluent treatment plants (ETP)

- Pump houses and cooling towers

- Fire detection and firefighting systems

- Lightning rods and interception systems

- Surge protection for motor control panels

- Earthing and bonding of exposed metallic structures

- Open and exposed working areas

- Tall metallic structures and masts

- Long outdoor power cable runs

- Frequent equipment movement zones

- Water treatment plants (WTP)

- Effluent treatment plants (ETP)

- Pump houses and cooling towers

- Fire detection and firefighting systems

- Lightning rods and interception systems

- Surge protection for motor control panels

- Earthing and bonding of exposed metallic structures

- Exposure to step and touch voltages

- Occupied and high-traffic zones

- Safety system power dependency

- Statutory and insurance compliance

LPES—Enterprise-Grade Lightning & Surge Protection Partner

- Lightning arresters and air termination systems as per IEC 62305

- Surge Protection Devices (Type 1, Type 2, Type 3)

- Earthing electrodes and grounding systems asper IS 3043 (indian Context)