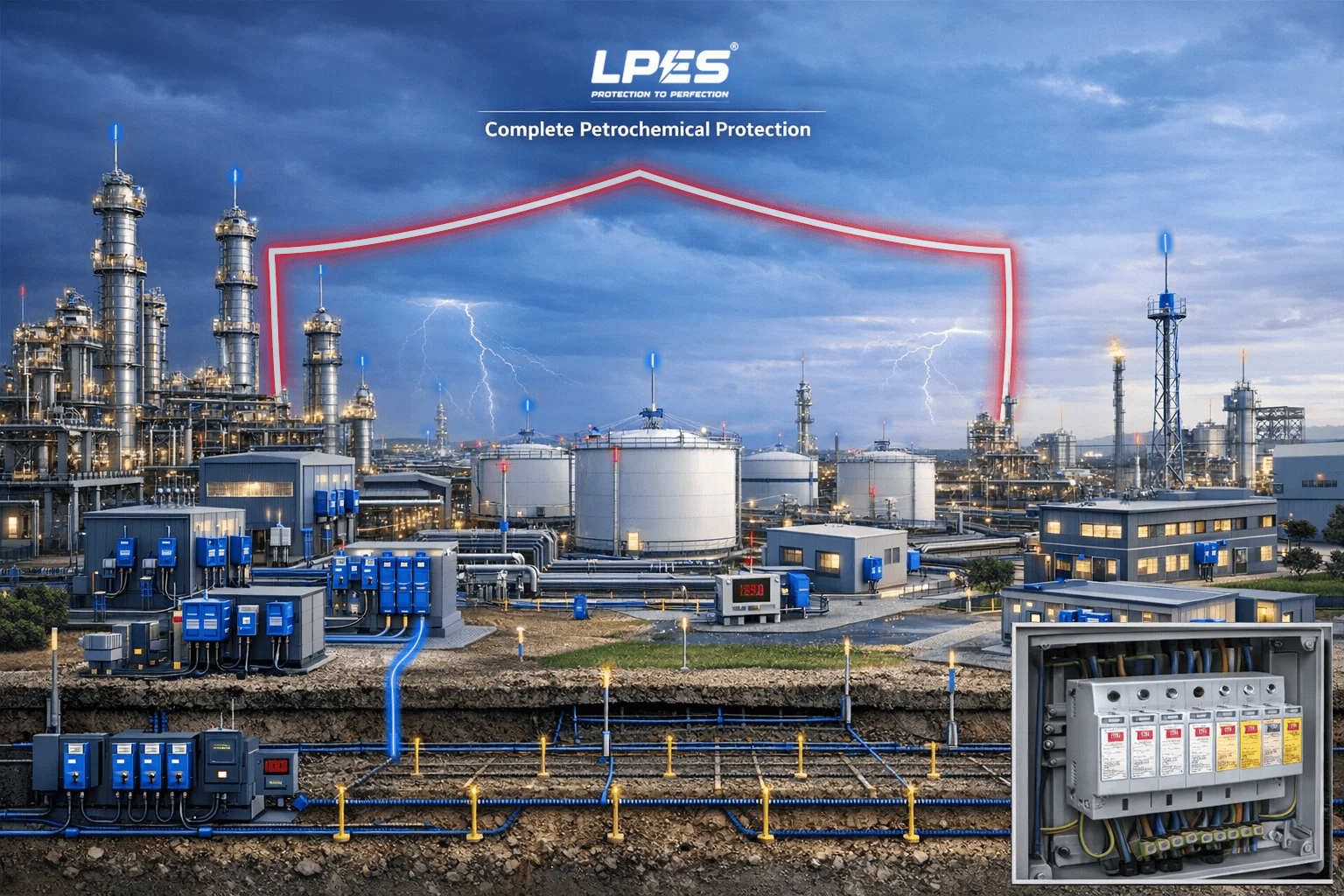

Securing Process Plants, Storage Facilities, Critical Assets, Digital Systems & Human Life

In the petrochemical industry, lightning is not merely a natural phenomenon—it is a high-energy ignition source capable of triggering fires, explosions, environmental damage, extended shutdowns, and irreversible reputational loss. With vast process plants, hazardous storage zones, high-energy electrical systems, and digitally controlled operations functioning continuously, comprehensive lightning and surge protection becomes a fundamental pillar of industrial safety and business continuity.

LPES Lightning and Surge Protection Solutions provide a fully engineered, standards-compliant framework designed to protect petrochemical buildings, warehouses, production and process units, electrical infrastructure, pipelines, digital systems, manpower databases, and human life—ensuring operational resilience, statutory compliance, and long-term asset integrity.

A Holistic Lightning Protection Philosophy for Petrochemical Facilities

Effective lightning protection in petrochemical environments demands more than isolated lightning arresters. It requires a layered, coordinated and risk-engineered approach that safely intercepts,conducts, controls, and dissipates lightning energy—while eliminating internal surge propagation and static hazards.

Lightning Protection in Petrochemical Industries Is Designed in 3 Layers

LPES solutions are engineered to mitigate:

- Direct lightning strikes

- Induced and conducted electrical surges

- Ground potential rise

- Static electricity accumulation

Across both hazardous and non-hazardous plant zones.

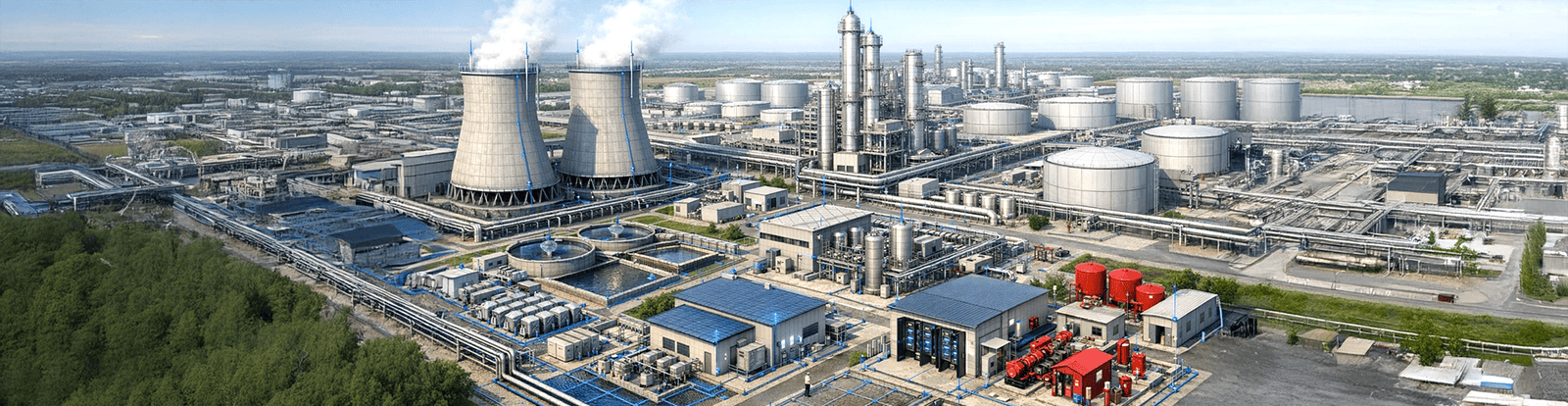

Protection of Process Plants & Production Units

Petrochemical production units operate under extreme temperature, pressure, and flammable conditions. Even a single uncontrolled lightning event can escalate into a catastrophic incident.

- Reactors, distillation columns, cracking units

- Compressors, pumps, and heat exchangers

- Process sheds and operating structures

- Control rooms within plant boundaries

- Utility units, including boilers and compressed air systems

- Air termination systems and lightning masts

- Down conductors routed outside hazardous zones

- Equipotential bonding of all metallic structures

- Type 1 & Type 2 Surge Protection Devices for process panels and MCCs

- Direct lightning on exposed equipment

- Surges via power/control systems

- Ground potential rise → step & touch voltages

- Poor bonding → sparks in flammable zones

- Equipment failure → process instability & shutdowns

- Raw material warehouses

- Finished product storage buildings

- Chemical and solvent storage warehouses

- Lightning-induced fires

- Electrical surge damage

- Large-scale material and inventory loss

- Roof-mounted lightning arresters

- Integrated earthing and bonding systems

- Surge protection for lighting, power, and ventilation systems

- Crude oil and chemical storage tanks

- LPG, LNG, and solvent tanks

- Floating roof and fixed roof tanks

- Type 1 SPDs at service entrances

- Type 2 SPDs at downstream distribution boards

- Low-impedance earthing systems

- Surge event counters and monitoring devices

- High ignition and explosion probability

- Flammable vapor and gas presence

- Static charge accumulation risks

- Direct lightning strike exposure

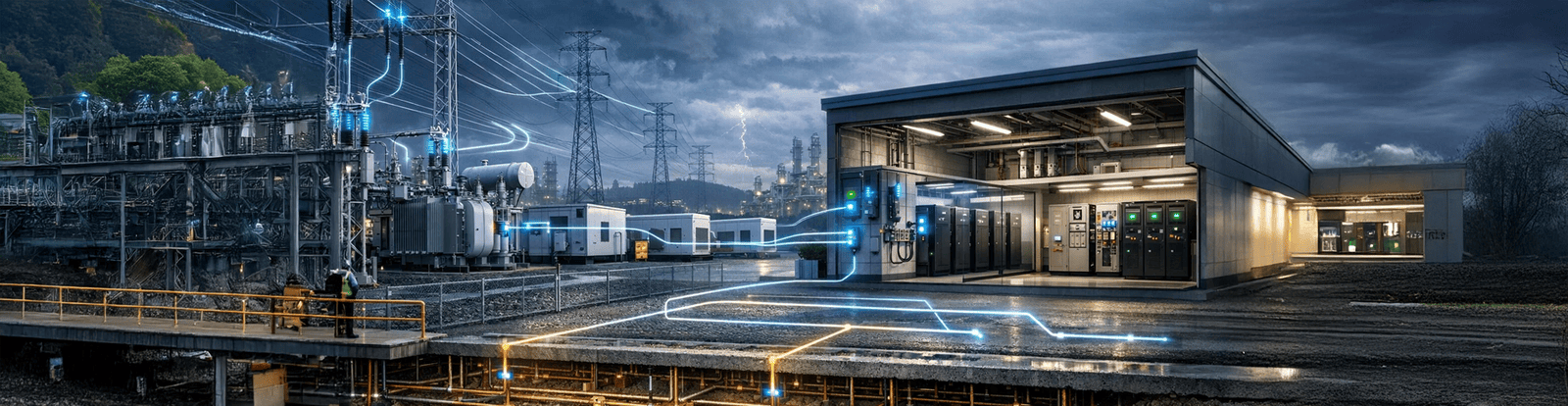

- HV/LV substations

- Switchyards and transformers

- DG sets and emergency power systems

- UPS rooms and critical power infrastructure

- Type 1 SPDs at service entrances

- Type 2 SPDs at distribution boards

- Low-resistance earthing grids

- Surge event counters and monitoring devices

- Primary entry of lightning-induced surges

- High fault and transient current level

- Sensitive and mission-critical equipment

- Plant-wide surge propagation paths

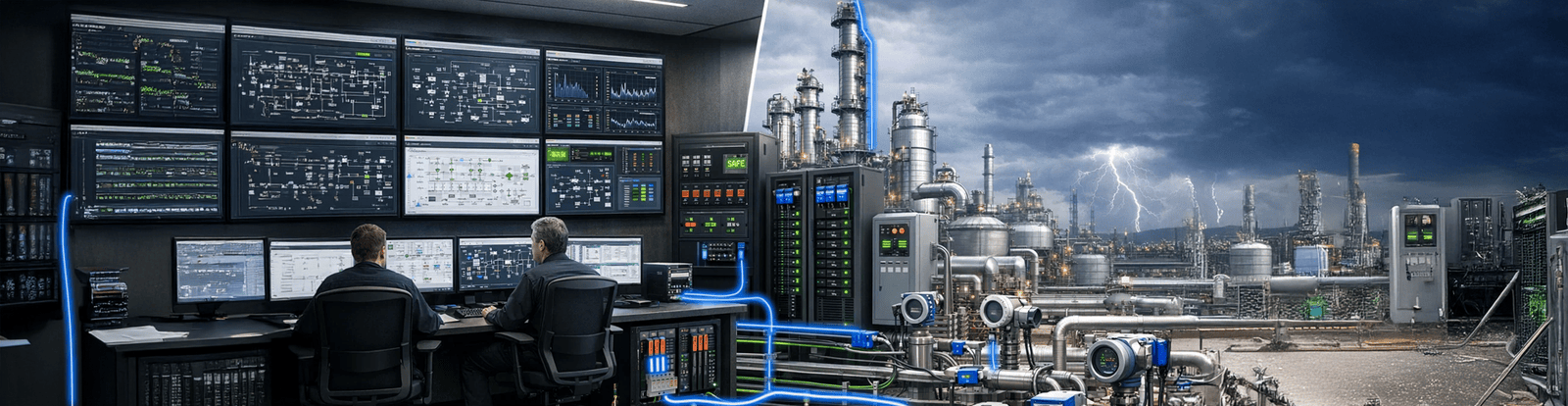

- PLC, SCADA, and DCS systems

- Safety Instrumented Systems (SIS)

- Fire & gas detection systems

- Field instruments, analyzers, and transmitters

- Type 3 SPDs at equipment level

- Data and signal line surge protection

- Shielded cabling practices

- Equipotential grounding

- Lightning-induced and switching surges on power and signal lines

- Data corruption and loss of production records

- Automation downtime affecting throughput and supply chains

- Above-ground pipelines and pipe racks

- Transfer manifolds and valve stations

- Truck, rail, and marine loading terminals

- Lightning masts and spark gaps for open and exposed areas

- Bonding and earthing of pipelines

- Surge protection for actuators, sensors, and metering systems

- Direct lightning strikes on exposed pipelines and racks

- Induced surges affecting actuators, sensors, and metering systems

- Static electricity buildup during product transfer operations

- Cooling towers

- Water and effluent treatment plants

- Air separation and utility units

- Lightning rods and air terminals

- Surge protection for motor control panels

- Earthing of all metallic and structural elements

- Lightning exposure to tall, open, and metallic utility structures

- Surge propagation through long feeder cables and motor circuits

- Failure of utility motors, pumps, and control panels due to transient overvoltages

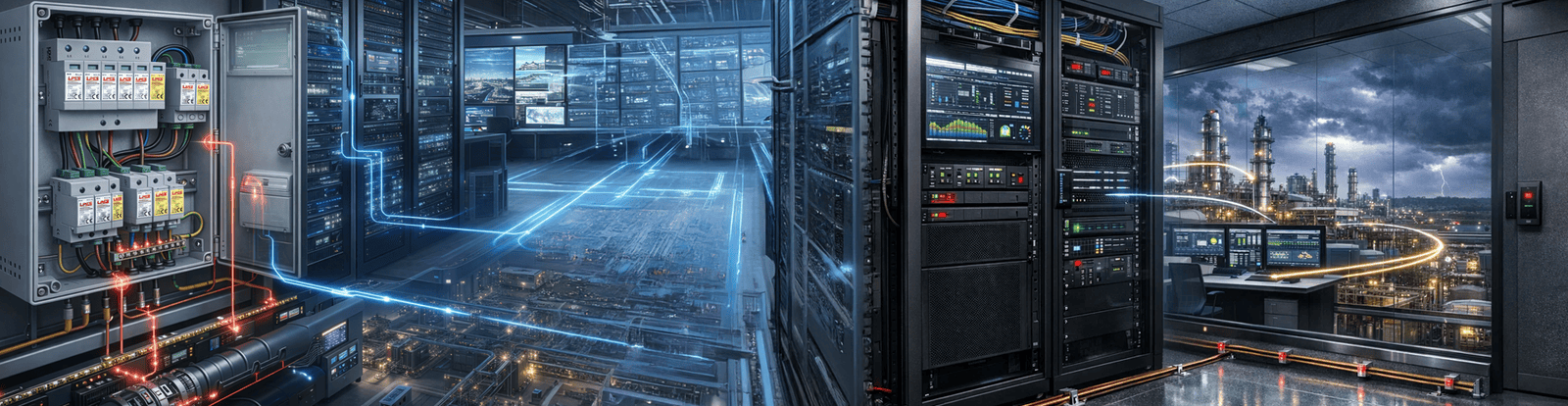

- Data centers and server rooms

- Communication networks

- Control system databases

- Communication and data line SPDs

- Dedicated IT earthing systems

- Equipotential bonding for network equipment

- Lightning-induced surges entering through power, data, and communication lines

- Electromagnetic interference affecting data integrity and network stability

- Ground potential differences causing equipment damage and data corruption

- Offices and control buildings

- Security cabins

- Emergency shelters and assembly points

- Personnel and visitor safety

- Business continuity

- Compliance with statutory insurance, and HSE requirements

- Structural lightning protection systems

- Power and data surge protection

- Step and touch voltage control

LPES—A Single Brand for Complete Petrochemical Protection

Every solution deployed across petrochemical facilities is 100% LPES-engineered, including:

- Lightning arresters and air termination systems

- Early Streamer Emission (ESE) solutions

- Surge Protection Devices (Type 1, Type 2, Type 3)

- Earthing electrodes and grounding systems

- Bonding accessories and lightning counters

LPES: Engineering Safety, Continuity & Compliance for Petrochemical Industries:

With LPES Lightning and Surge Protection Solutions, petrochemical organizations protect infrastructure,production, assets, digital intelligence, and human life, creating a resilient operational environment where safety, compliance, and performance coexist—without compromise.