Safeguarding GMP Facilities, Critical Assets, Digital Integrity & Human Life

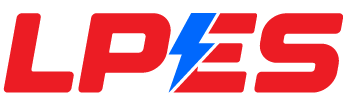

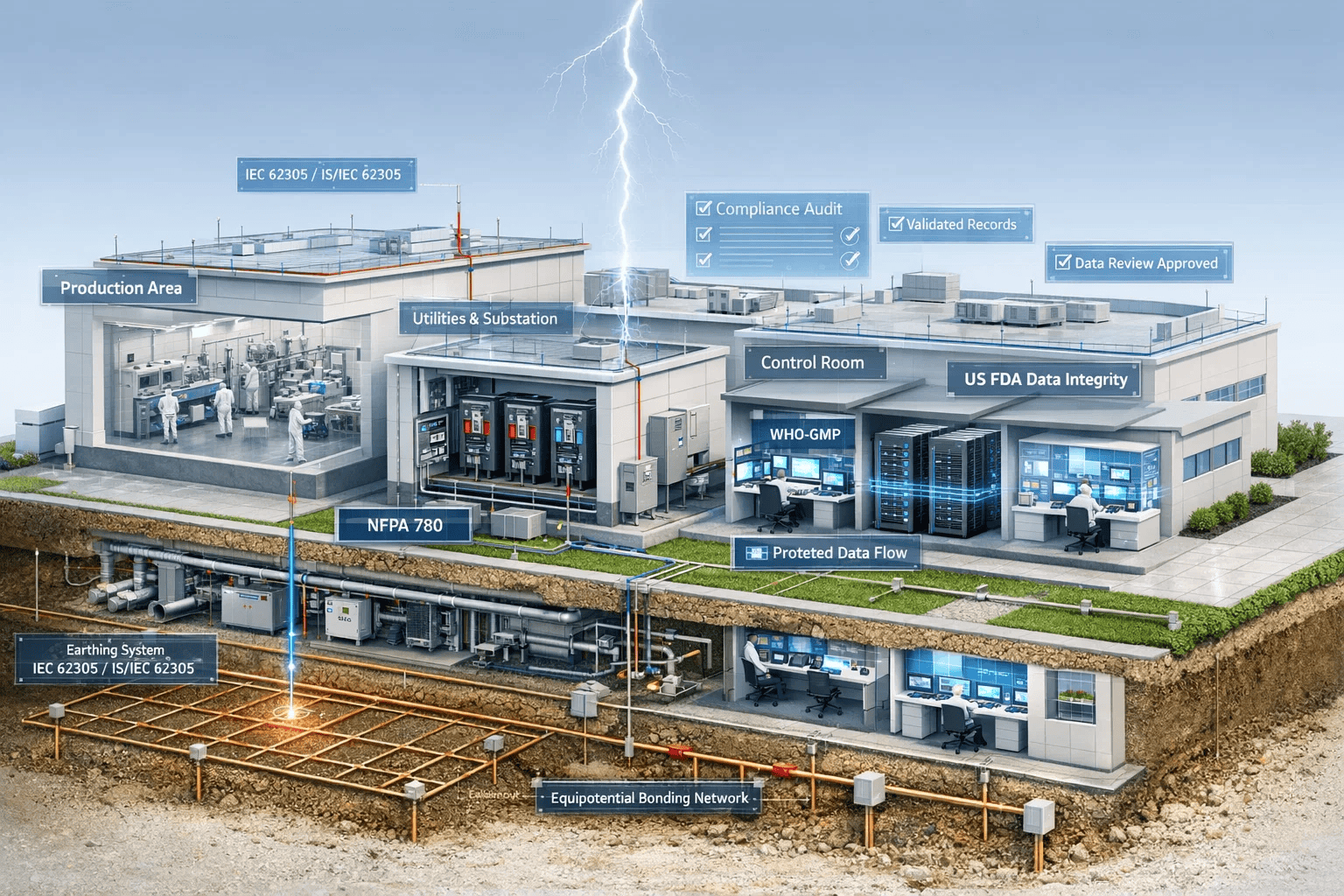

Lightning protection in the pharmaceutical industries is designed in three integrated layers:

- External Lightning Protection System (LPS)

- Internal Surge Protection Devices (SPDs)

- Earthing, Bonding & Equipotential Grounding

LPES solutions control lightning energy from interception to safe dissipation, mitigating:

- Direct lightning strikes

- Induced over voltages and switching surges

- Ground potential rise

- Electrostatic discharge (ESD)

This ensures uninterrupted, validated pharmaceutical operations and long-term asset protection.

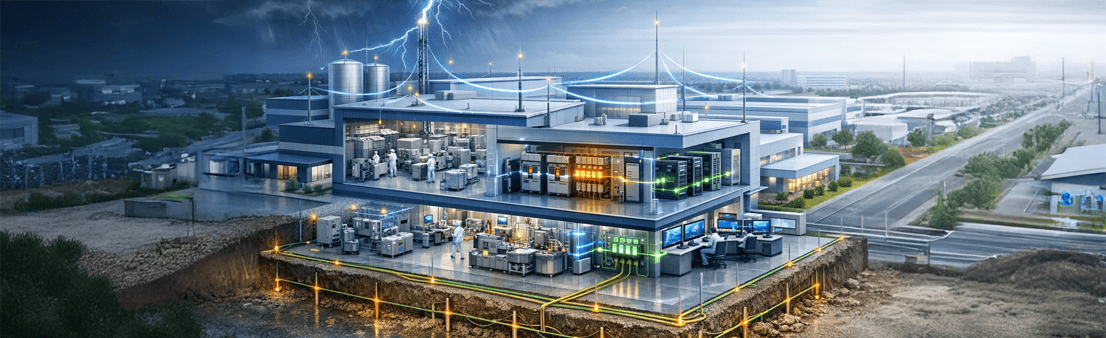

Manufacturing & Production Areas

Pharmaceutical production environments operate under continuous, validated, and contamination-controlled conditions. Even momentary electrical disturbances can invalidate entire batches and disrupt patient supply chains

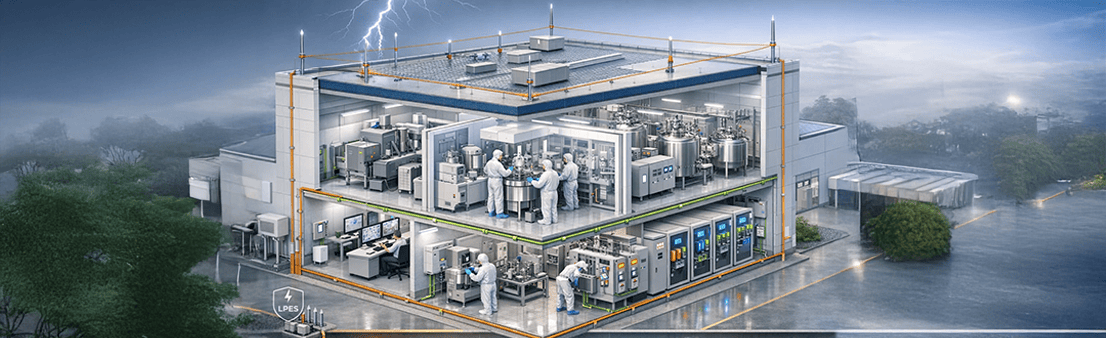

Protecting Inventory, Compliance & Business Continuity

Pharmaceutical warehouses store high-value APIs, excipients, intermediates, finished products, and temperature-sensitive formulations.

- Raw material warehouses

- API and excipient storage areas

- Finished goods warehouses

- Cold rooms and temperature-controlled storage

- Roof-mounted lightning arresters

- Earthing and bonding networks

- Surge protection for refrigeration ,lighting, and power systems

- High-value pharma inventory at lightning risk

- Temperature failures cause product loss

- Surges trigger compliance deviations

- Downtime disrupts business continuity

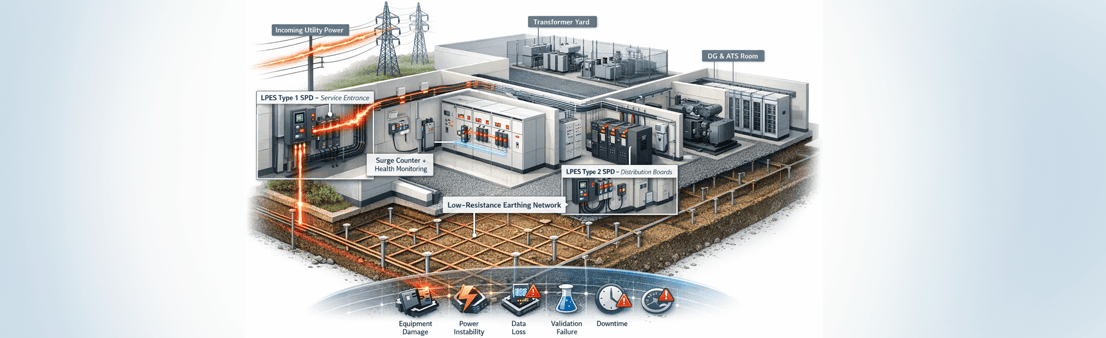

- HT/LT panels

- Transformers and substations

- DG sets and emergency power systems

- UPS rooms and critical power distribution

- Type 1 SPDs at service entrances

- Type 2 SPDs at distribution boards

- Low-resistance earthing systems

- Surge counters and monitoring devices

- Lightning/surges damage stored products

- Surges disrupt lighting & handling

- Refrigeration failure → temperature excursions

- Poor earthing/GPR → safety & compliance risk

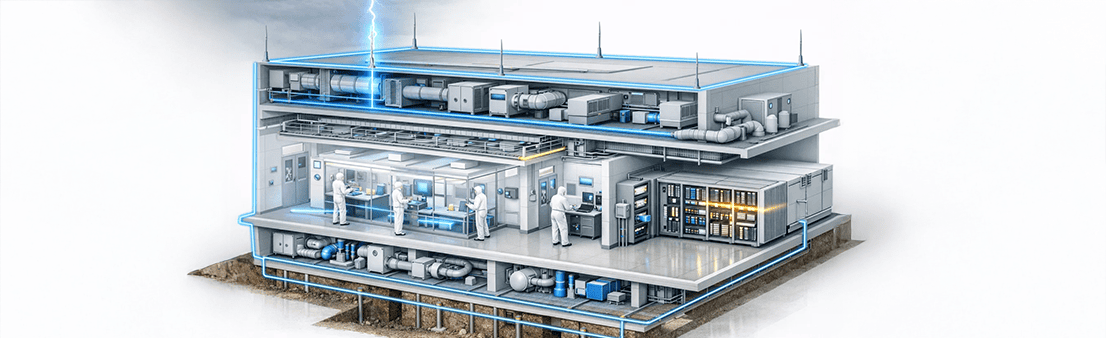

- HVAC systems

- AHUs, chillers, and BMS panels

- Environmental monitoring systems

- Surge protection for HVAC control panels

- Bonding of ducting and metallic structures

- Type 2 & Type 3 SPDs for control electronics

- Lightning & surges disrupt HVAC, AHUs, chillers & BMS

- Over voltages affect control electronics & sensors

- Monitoring failure → undetected GMP excursion

This prevents temperature, humidity, and pressure excursions that can compromise product quality.

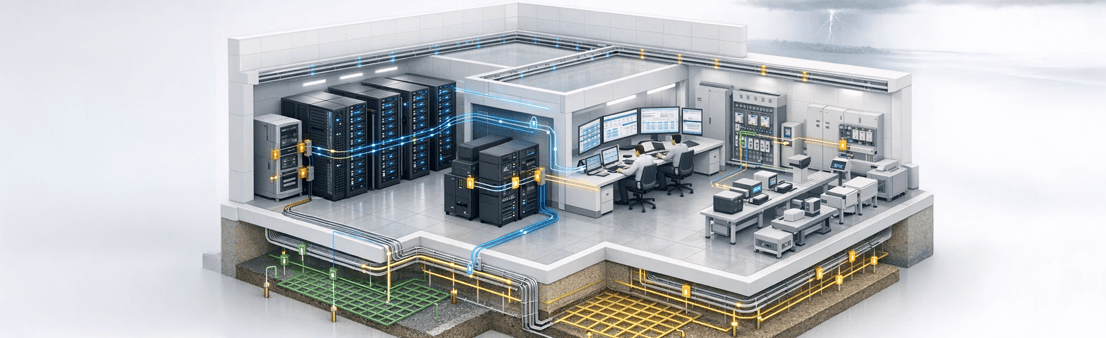

- ERP, MES, and LIMS servers

- PLC, SCADA, and BMS systems

- Batch records and serialization databases

- Weighing, barcode, and track-and-trace systems

- Type 3 SPDs at equipment level

- Data and signal line surge protectors

- Shielded cabling and equipotential grounding

- Dedicated IT earthing systems

- Surges impacting ERP, MES, LIMS, PLC, SCADA, and BMS

- Data loss in batch records, serialization, and audit trails

- Signal surges, EMI, and GPR causing system faults and downtime

These measures protect manpower databases, electronic batch records, audit trails, and regulatory data.

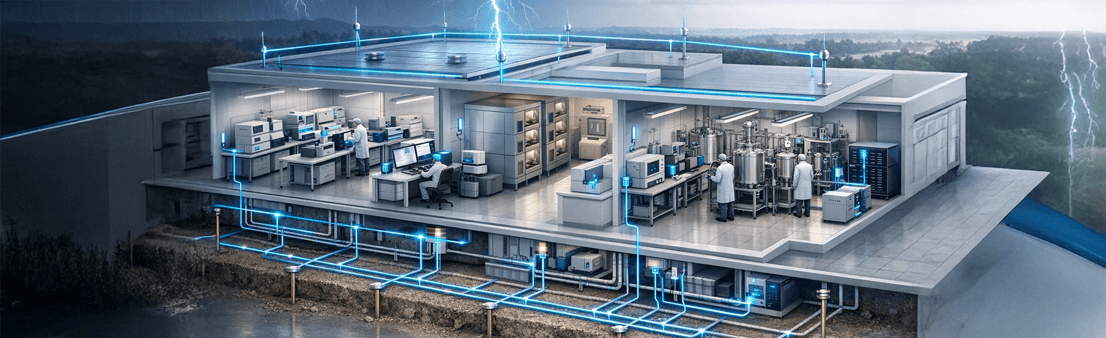

- QC and analytical laboratories

- Stability chambers

- R&D pilot plants

- Precision surge protection for sensitive instruments

- Structural lightning protection for laboratory buildings

- Equipment earthing and bonding

- Surges impacting ERP, MES, LIMS, PLC, SCADA, and BMS

- Data loss in batch records, serialization, and audit trails

- Signal surges, EMI, and GPR causing system faults and downtime

- Water for Injection (WFI) plants

- Purified water systems

- Effluent treatment plants (ETP)

- Compressed air and nitrogen systems

- Vaccine and biologics cold storage

- Lightning rods and air terminals

- Surge protection for motor panels

- Earthing of all metallic and utility structures

- Lightning & surges risk WFI, water, ETPs, and utility continuity

- Power overvoltage affects motors, compressors, air, nitrogen, and cold chains.

- GPR & poor earthing cause equipment damage and safety and compliance loss

- Office buildings and documentation centers

- Security cabins and access control systems

- Emergency systems and assembly points

- Structural lightning protection systems

- Power and data SPDs

- Step and touch voltage control

- High occupancy increases human exposure

- Lightning and surge events pose shock risks

- Fire hazards threaten occupant safety

- System failures disrupt safe evacuation

Why LPES for Pharmaceutical Lightning Protection

- End-to-end lightning and surge protection under a single trusted brand

- Engineered for GMP compliance, data integrity, and auditreadiness

- Protects infrastructure, assets, production, digital systems, and human life

- Reduces downtime, batch loss, and compliance risk